Description

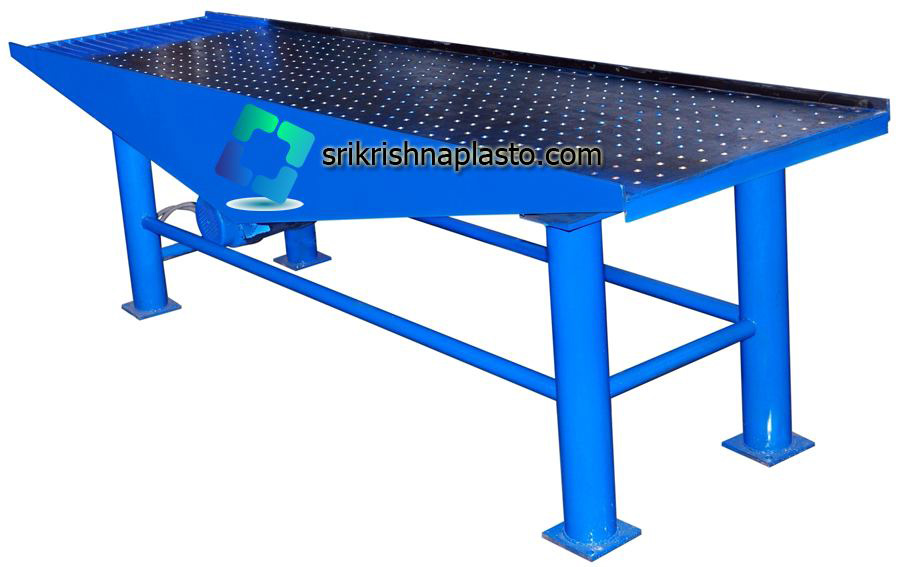

Vibrating Table Standard Model

We are involved in the provision of a “Vibrating Table for concrete paver blocks manufacturers”. http://www.srikrishnaoverseas.com vibrating table is easy to install and operate, no further maintenance and care required.

http://www.srikrishnaoverseas.com Vibrating Table is highly durable, highly effective anti-corrosive. on vibrating table related issue Customer specifications are also supported. make

We are committed to an excellent selection of Barrings with key role in maintain speed.

The automotive industry uses Barrings and these Steel are available that meet the requirements according to the needs and requirements.

We offer these Barrings at market prices in the foreground.

http://www.srikrishnaoverseas.com We offer a range of high precision machinery for a concrete paving blocks factory.

all kinds of Concrete Pavers, Concrete Floor tiles, Concrete wall tiles taking into account the requirements of the applications of the construction industry. Our range of engineering works are presented in accordance with international standards. These machines are being developed and evaluated with precision

How to use Vibrating Table for making colored Paving Block Brick/Floor Tiles/Wall Tiles is very simple.

You need two Vibrating table, 1 for colored mixture ( for Top layer ) and 1 base layer concrete mixture.

on 1st Vibrating table you have to fill 7-10MM of thick layer in the modules and this will move same on the vibration table as shown in the video. Please give 45-60 seconds Time for vibration.

on the 2nd Vibrating table is to be place where the first Vibrating table ends, now you have to fill concrete mixture in the PVC moulds containing color mixture same as show in video. after filling concrete mixture on the mould Please give 45-60 seconds Time for vibration again.

Vibrating machines that are fixed to formwork or casting tables or as vibrating screeds to consolidate wet concrete.

Increases compressible strength and bond between concrete and rebar and decreases concrete permeability. Decreases cold joints, honeycombing, excessive entrapped air, and segregation, Causes concrete within a circular field of action to act like a liquid

almost said in the definition above that vibrators are used to remove entrained air, but of course some concrete products have air purposely entrained to make them lightweight so I’ll use the terms gross voids and entrapped air pockets.

As a very rough rule of thumb it has been said that up to 20% of the material coming out of the back of a transit mixer is air, trapped in the concrete. We have to remove it and the way we do it is to apply vibration to it when it is placed in it’s final position, while it is still in a liquid state.

Vibrating Table Features :-

Sri Krishna Plasto vibrating table are very user-friendly

Sri Krishna Plasto vibrating table are High efficiency

Our Vibrating Table Trouble-free operation

Vibrating Table low noise

Properly equipped with the motors and allow another to ensure proper operation

Low power consumption

Our Vibrating Table Low maintenance

- Vibrating Table Motor 2HP.

- Vibrating Table 3Phase.

- Vibrating Table Motor Have 12 Month replacement warranty*.

- For Vibrating Table You need Just Power Connection its like a Plug and Play Vibrator Tables.

- Vibrating Table Size 10 Feet Long X 2.5 Feet width.

- Vibrating Table Packing Charge Extra If required in Wooden Box.

- Vibrating Table Freight Extra.

- Tax as per applicable.